News

-

Twin Chain Spread Smart

2017-12-12

Utilise the GPS technology with Spreadsmart 1020p Twin Chain Pomot have developed spreading...

-

Spreader with hydraulic drive chain conveyor and TeeJet500

2017-01-31

UPR spreaders with hydraulic chain drive and computer control TeeJet 500. To meet the expectations...

-

New gold medal in Kielce

2011-09-13

Multifunction vacuum type T513 features include a suction frame and completely innovative...

Twin Chain Spread Smart

Utilise the GPS technology with Spreadsmart 1020p

Twin Chain

Pomot have developed spreading hardware that can be fully controlled to utilize the GPS technology which is common place in the modern spreading industry. The Transpread patented Twin Chain technology allows full control of the spreader output to either side of the vehicle. Pomot is in the process of combining these two key areas by allowing the spread rate out either side to be automatically influenced by the GPS position of the vehicle.

The GPS systems currently available through competitors are only able to map, or change the over all rate based on the GPS position. The pictures shown here were taken by GPS software showing that even with the best GPS guidance, a driver still has to drive to the conditions. These unavoidable errors cannot be adjusted for, except with a Pomot Twin Chain spreader. By adding GPS technology to older spreaders, they will not be able to take advantage of this innovative, patented technology.

The GPS systems currently available through competitors are only able to map, or change the over all rate based on the GPS position. The pictures shown here were taken by GPS software showing that even with the best GPS guidance, a driver still has to drive to the conditions. These unavoidable errors cannot be adjusted for, except with a Pomot Twin Chain spreader. By adding GPS technology to older spreaders, they will not be able to take advantage of this innovative, patented technology.

Make sure your next spreader is a POMOT Twin Chain to benefit from this.

One of the most common causes of uneven application in the field is the frequent stopping and starting of the spreader on the headlands. The new POMOT control software will be able to automatically stop and start in the correct position with no input from the driver. Where necessary it will also be able to start or stop only one side and/or reduced the rate on either side if required.

One of the most common causes of uneven application in the field is the frequent stopping and starting of the spreader on the headlands. The new POMOT control software will be able to automatically stop and start in the correct position with no input from the driver. Where necessary it will also be able to start or stop only one side and/or reduced the rate on either side if required.

Give your operators the equipment allowing them to do a job they can be proud of, while providing the best service for the customer and protecting the environment.

Fertiliser savings from 10 to 30%

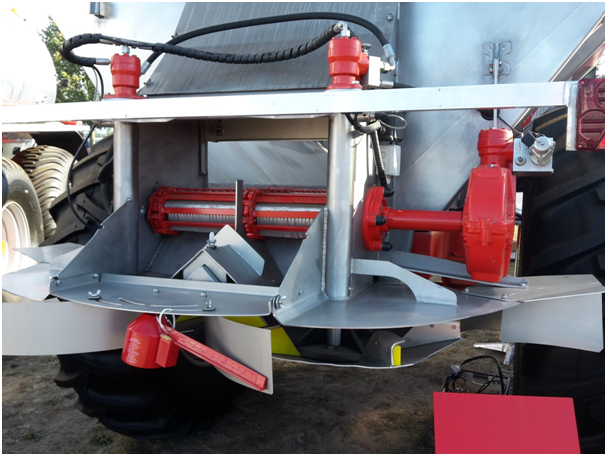

A 730 twin chain (shown), gives a clear base with no extra obstructions, minimising problems with difficult products.

A 730 twin chain (shown), gives a clear base with no extra obstructions, minimising problems with difficult products.

This will spread anything a single chain or belt spreader will do, but control the product better. A wireless link from the Cab to the Bin reduces maintenance and installation costs, making it for easier trouble shooting. There is a large screen size for easy viewing, allowing all needed functionality to be displayed while spreading.

Some systems which claim to be as good only provide a ‘stop/start’ function for the chain control.

Some systems which claim to be as good only provide a ‘stop/start’ function for the chain control.

POMOT has patented capability covering the use of full variable control on each side, under the influence of GPS.

The picture opposite shows a run where the driver is able to reduce the width when on the overlap. This saves fertiliser and provides an even spread. Shortly this will automatically be carried out by the on-board POMOT computer, based on the trucks GPS position. This is patented technology so will only be possible with a Transpread spreader.

Stay one step ahead of the competition and reap the benefits. Give your clients the results they deserve at market beating prices.

On a field like this, you could expect to use 10 to 30% less fertiliser with a fully controllable spreader.

Spreadsmart 1020

Tablet Cab Control Unit (CCU)

·Full control of your spreader from the comfort of your cab.

·Wireless link from Cab to Bin. No wires, no plugs.

·GPS guidance and data upload can be printed free on Google Maps. No monthly fees.

Powered Hub

12 or 24V input, no voltage dropper required. Rough Service powered hub.

Charge tablet and has sealed connections and BT to connect to the FCU.

Spreader with hydraulic drive chain conveyor and TeeJet500

UPR spreaders with hydraulic chain drive and computer control TeeJet 500.

To meet the expectations of our customers, company POMOT put in offer fertilizer and lime spreaders controlled by a computer.

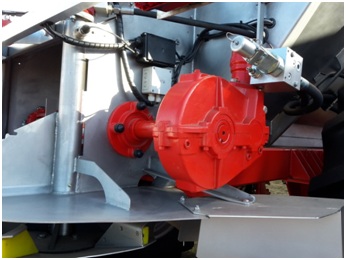

The standard 3-speed gearbox which drives the chain conveyor has been replaced with a hydraulic gearbox from RÖGELBERG. The hydraulic gearbox it’s driven by a hydraulic motor, which to the full (maximum) capacity needs 60l of oil from the pump of the tractor.

The standard 3-speed gearbox which drives the chain conveyor has been replaced with a hydraulic gearbox from RÖGELBERG. The hydraulic gearbox it’s driven by a hydraulic motor, which to the full (maximum) capacity needs 60l of oil from the pump of the tractor.

Speed of the hydraulic motor is controlled by electro-hydraulic proportional valve connected to a TeeJet computer installed in the tractor cab.

Speed of the hydraulic motor is controlled by electro-hydraulic proportional valve connected to a TeeJet computer installed in the tractor cab.

Spinner drive work without change like in all POMOT spreader and it is done with a hydraulic pump from the tractor. POMOT build on the 500chain spreader (UPR 4 and UPR 7) the hydraulic motor with 50 cc (need 50l/min) and on the spreader with chain 730mm (UPR 10, UPR 12,5) hydraulic motor with 80cc (need 80l/min). To set up the spinners speed (work width ) You have to use manual oil flow valve build on the front of the bin.

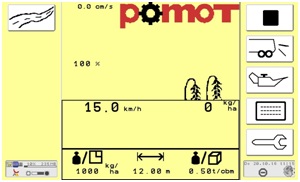

Computer TeeJetLH 500 enables a more functions what are not available by spreader wit standard 3-gear conveyor drive with jockey wheel.

Computer TeeJetLH 500 enables a more functions what are not available by spreader wit standard 3-gear conveyor drive with jockey wheel.

Addtional functions:

1. Starting and stopping the chain conveyor from the tractor cab.

With one button you can start the flow of oil to run the chain conveyor at the correct speed. This feature allows to save material, it does not spread on wasteland and the water ponds, etc. And the material is spreaded where appropriate.

2. Adjusting the rate of fertilizer and lime from the tractor cab.

Thanks button + / - the rate can be change from the set at begining 100% up to 300% and that same way reduce to 1%. The rate reduce steps can be changed according setting. Thanks that there is a possibility to spread higher rate there where You need it without additional drive thru over the area where more fertilizer or lime is needed.

3. Saving settings spreader after calibration.

After calibration for the spreaded material the computer TeeJet have possibility to save the settings. That allows You to save up to 100 calibration for 100 different materials which are usually spreading. To that save data, you can always return at any time, so that in the next season You do not have to do the calibration once more time for the same material.

If the spreader is working as contractors service the TeeJet enables you to divide the spreading materials for individual customers or orders.

4. The unloading.

Fertiliser spreader with hydraulic drive of conveyor have the UNLOADING function. You can easy unload from the bin the remaining fertilizer or lime. The function it easy to ON in TeeJet computer.

5. Warning - low quantity of material in the tank..

Thanks to the built-in the bin low quantity sensor the TeeJet let you know abut the low level of the material in the spreader. Thank that the operator will be abpe to already prepare for the end of the spreading and next loading. That give him exactly spreading point, he will not miss the spreading area and it will easy to him the job.

6. Displaying the most important data for the operator.

The computer displays the following information:

· Speed of the spreader km/h

· The current rate kg/ha

· Spreading width - in meters

· The amount of material in the binj

· Already spread area

· The remained area to spread

· Operating hours counter

7. Save and archiving done works and jobs.

TeeJet 500 computer thanks the memory can save data related to all the works that spreader made. This information can be backed up when connected to a computer and printed as confirmation of the done job.

The stored data hold following information:

a. Date when the job was done

b. Operator name

c. Customer name / number of the field

d. Spread material

e. Rate of the material

f. Area

g. Spreading work width

8. ISOBUS -Compatible with universal control bus

UPR spreader equipped with a TeeJet 500 computer can be equipped on request with a universal terminal ISO BUS present in modern tractors. Connecting terminal spreader to the tractor runs the service menu of the POMOT spreader on the ISO BUS screen in tractor cab. The ISO BUS will recognize the spreader and display the spreader menu and POMOT logo.

UPR spreader equipped with a TeeJet 500 computer can be equipped on request with a universal terminal ISO BUS present in modern tractors. Connecting terminal spreader to the tractor runs the service menu of the POMOT spreader on the ISO BUS screen in tractor cab. The ISO BUS will recognize the spreader and display the spreader menu and POMOT logo.

9. GPS and map-reading function soil fertility

The computer TeeJet 500 can be extended with exactly and proven GPS system to control and monitor of the spreader work. The GPS system also has the function of reading the map soil fertility and thank that it will control the spreader according the soil map and spread the rate according map request. Thanks that addtionaly computer will control spreader itself and set up the rate of the fertilizer according map request.

The computer TeeJet 500 can be extended with exactly and proven GPS system to control and monitor of the spreader work. The GPS system also has the function of reading the map soil fertility and thank that it will control the spreader according the soil map and spread the rate according map request. Thanks that addtionaly computer will control spreader itself and set up the rate of the fertilizer according map request.

10. Wheels size according Your request.

The hydraulic drive of the chain conveyor POMOT company can offer any size of wheels for fertilizer, because there is no limit in the size like on standard 3-gear box with jockey wheel. This allows fertilizer spreading the second and third dose.

11. To drive the chain conveyor it need from min. 40 up to 60 l/min of oil.

12. To drive the spinners it need max. 80l/min.

It is enough when the tractor have at least 100 l/min oil pump.

Slurry tank type T-513

Slurry tank type T-513 was created for farmers operating on their own as well as other farms. Thanks to its plenteous equipment it may also be used for additional purposes i.e. emptying adjacent sewage plants and cleaning sewage systems. It may also be used in municipal enterprises.

Usage:

Slurry tank type T-513 is to be used for:

- Removal, transport and pumping liquid manure from underground and reservoirs as well as surface reservoirs with highly situated drawing points,

- Diffusion of liquid manure on farms, meadows and pastures,

- Preparation, blending and diffusion of RSM liquid fertilizers on farms,

- Removal of waste and sediments from 6m deep sewers, pits and cesspools,

- Cleaning ponds, reservoirs of ooze and mud,

- Maintenance of adjacent sewage plants,

- Transport of water for farms watering,

- Supplying drinking-troughs,

- And fire-fighter actions.

Main elements of equipment:

1. Suspension made of closed bars with special reinforcements mounted on BOGIE tire set (tandem with springs) with 23.1 x 26 tires and rear axis, prepared to drive on public roads with 40 km/h speed.

2. Suspension prepared for injectors with control from tractor cabin

3. Special steering system for the rear axis which enables steering the rear wheels so they turn together with the car

4. Hydraulically powered MORO compressor type PM 80, which because of its special construction enables continuous work for over an hour keeping normal work temperature. The MORO compressor is also equipped with automatic vane greaser which facilitates operating the tank.

5. MORO rotary suction arm enabling 320 degree rotation as well as the ability of lowering and rising the arm +/- 27 degree. Controlled totally hydraulically with added remote control which has absolutely no problem with emptying underground or surface reservoir.

http://w.pomot.pl/en/news-archive.html#sigProIddaad06afb1

New gold medal in Kielce

Multifunction vacuum type T513 features include a suction frame and completely innovative electronic system for measuring the nitrogen content and nutrients in the manure NPK2 Fertimeter company, was awarded the Gold Medal AGROTECH Fair held at the weekend 11 - 13 March 2011. in Kielce.