UPR spreaders with hydraulic chain drive and computer control TeeJet 500.

Company POMOT have in offer fertilizer and lime spreaders with hydraulic conveyour drive controlled by a computer.

POMOT can offer each of the spreader with TeeJet computer.

UPR 2, UPR 4, UPR 7, UPR 10, UPR 12,5, UPR 16, UPR 18., UPR 27

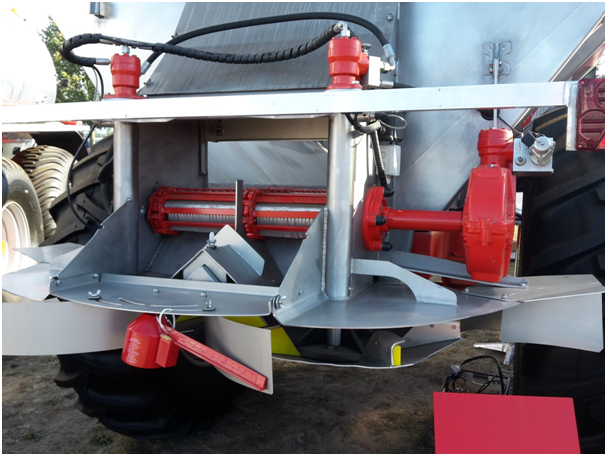

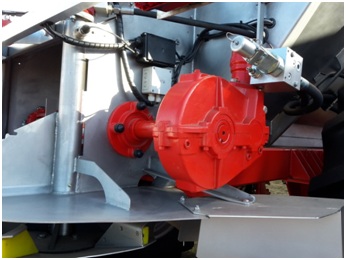

The standard 3-speed gearbox which drives the chain conveyor has been replaced with a hydraulic gearbox from RÖGELBERG. The hydraulic gearbox it’s driven by a hydraulic motor, which to the full (maximum) capacity needs 60l of oil from the pump of the tractor.

The standard 3-speed gearbox which drives the chain conveyor has been replaced with a hydraulic gearbox from RÖGELBERG. The hydraulic gearbox it’s driven by a hydraulic motor, which to the full (maximum) capacity needs 60l of oil from the pump of the tractor.

Speed of the hydraulic motor is controlled by electro-hydraulic proportional valve connected to a TeeJet computer installed in the tractor cab.

Speed of the hydraulic motor is controlled by electro-hydraulic proportional valve connected to a TeeJet computer installed in the tractor cab.

Spinner drive work without change like in all POMOT spreader and it is done with a hydraulic pump from the tractor. POMOT build on the 500chain spreader (UPR 4 and UPR 7) the hydraulic motor with 50 cc (need 50l/min) and on the spreader with chain 730mm (UPR 10, UPR 12,5) hydraulic motor with 80cc (need 80l/min). To set up the spinners speed (work width ) You have to use manual oil flow valve build on the front of the bin.

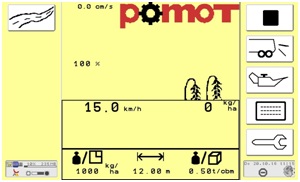

Computer TeeJetLH 500 enables a more functions what are not available by spreader wit standard 3-gear conveyor drive with jockey wheel.

Computer TeeJetLH 500 enables a more functions what are not available by spreader wit standard 3-gear conveyor drive with jockey wheel.

Addtional functions:

1. Starting and stopping the chain conveyor from the tractor cab.

With one button you can start the flow of oil to run the chain conveyor at the correct speed. This feature allows to save material, it does not spread on wasteland and the water ponds, etc. And the material is spreaded where appropriate.

2. Adjusting the rate of fertilizer and lime from the tractor cab.

Thanks button + / - the rate can be change from the set at begining 100% up to 300% and that same way reduce to 1%. The rate reduce steps can be changed according setting. Thanks that there is a possibility to spread higher rate there where You need it without additional drive thru over the area where more fertilizer or lime is needed.

3. Saving settings spreader after calibration.

After calibration for the spreaded material the computer TeeJet have possibility to save the settings. That allows You to save up to 100 calibration for 100 different materials which are usually spreading. To that save data, you can always return at any time, so that in the next season You do not have to do the calibration once more time for the same material.

If the spreader is working as contractors service the TeeJet enables you to divide the spreading materials for individual customers or orders.

4. The unloading.

Fertiliser spreader with hydraulic drive of conveyor have the UNLOADING function. You can easy unload from the bin the remaining fertilizer or lime. The function it easy to ON in TeeJet computer.

5. Warning - low quantity of material in the tank..

Thanks to the built-in the bin low quantity sensor the TeeJet let you know abut the low level of the material in the spreader. Thank that the operator will be abpe to already prepare for the end of the spreading and next loading. That give him exactly spreading point, he will not miss the spreading area and it will easy to him the job.

6. Displaying the most important data for the operator.

The computer displays the following information:

· Speed of the spreader km/h

· The current rate kg/ha

· Spreading width - in meters

· The amount of material in the binj

· Already spread area

· The remained area to spread

· Operating hours counter

7. Save and archiving done works and jobs.

TeeJet 500 computer thanks the memory can save data related to all the works that spreader made. This information can be backed up when connected to a computer and printed as confirmation of the done job.

The stored data hold following information:

a. Date when the job was done

b. Operator name

c. Customer name / number of the field

d. Spread material

e. Rate of the material

f. Area

g. Spreading work width

8. ISOBUS -Compatible with universal control bus

UPR spreader equipped with a TeeJet 500 computer can be equipped on request with a universal terminal ISO BUS present in modern tractors. Connecting terminal spreader to the tractor runs the service menu of the POMOT spreader on the ISO BUS screen in tractor cab. The ISO BUS will recognize the spreader and display the spreader menu and POMOT logo.

UPR spreader equipped with a TeeJet 500 computer can be equipped on request with a universal terminal ISO BUS present in modern tractors. Connecting terminal spreader to the tractor runs the service menu of the POMOT spreader on the ISO BUS screen in tractor cab. The ISO BUS will recognize the spreader and display the spreader menu and POMOT logo.

9. GPS and map-reading function soil fertility

The computer TeeJet 500 can be extended with exactly and proven GPS system to control and monitor of the spreader work. The GPS system also has the function of reading the map soil fertility and thank that it will control the spreader according the soil map and spread the rate according map request. Thanks that addtionaly computer will control spreader itself and set up the rate of the fertilizer according map request.

The computer TeeJet 500 can be extended with exactly and proven GPS system to control and monitor of the spreader work. The GPS system also has the function of reading the map soil fertility and thank that it will control the spreader according the soil map and spread the rate according map request. Thanks that addtionaly computer will control spreader itself and set up the rate of the fertilizer according map request.

10. Wheels size according Your request.

The hydraulic drive of the chain conveyor POMOT company can offer any size of wheels for fertilizer, because there is no limit in the size like on standard 3-gear box with jockey wheel. This allows fertilizer spreading the second and third dose.

11. To drive the chain conveyor it need from min. 40 up to 60 l/min of oil.

12. To drive the spinners it need max. 80l/min.

It is enough when the tractor have at least 100 l/min oil pump.